Imagine a furnace chamber so hot that metals turn to liquid. How do the walls of that furnace survive without melting or cracking? The answer lies in Refractories.

Refractories are the “protective armor” of industrial machinery. Unlike standard insulation, which merely minimizes heat loss, refractories are engineered to withstand direct exposure to extreme temperatures, chemical attacks, and severe mechanical wear. They are the critical liners inside kilns, reactors, and furnaces that keep industrial operations safe and stable.

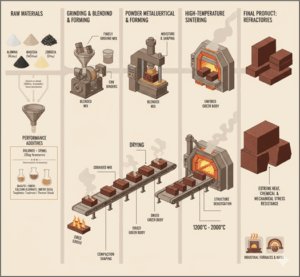

How It’s Made: The journey begins with robust raw materials like Alumina (Al2O3), Silica (SiO2), and Magnesia (MgO). These are finely ground, blended with binders, and subjected to sintering—a high-temperature firing process that densifies the structure, ensuring the final product is tough enough to endure thermal shock.

Figure 1: Refractory production

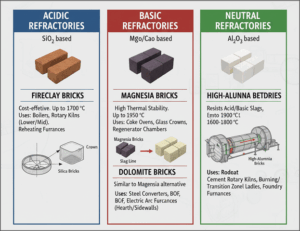

Choosing the Right Armor: Types of Refractories

| Type | Material Base | Max Temp | Ideal Application |

| Acidic | Fireclay & Silica | 1650 to 1700 °C | Glass & Coke: Used in glass tank crowns and coke ovens where resistance to acidic gas is vital. |

| Basic | Magnesia & Dolomite | > 1900 °C | Steel: Essential for steel-making converters and electric arc furnaces, resisting basic slags and extreme heat. |

| Neutral | High-Alumina | 1600 to 1800 °C | Cement: For cement rotary kilns and ladles, balancing resistance to both chemical attack and physical stress. |

Figure 2: Refractories classifications and applications

Why It Matters?

For plant owners, refractories are not just a purchase; they are an investment in efficiency. While high-grade options (like spinel-based bricks) cost more upfront, the Return on Investment (ROI) is substantial.

Real-World Impact:

- Reduced Maintenance: A plant in Tamil Nadu extended their refractory life from 10 to 24 months, saving Rs 4 crore annually by reducing shutdowns.

- Fuel Savings: Advanced refractories have 20-30% lower thermal conductivity. A Madhya Pradesh plant used this to cut fuel use by 6%, saving Rs 3.5 crore annually.

- Sustainability: Better thermal efficiency reduces CO2 emissions—cutting roughly 0.1 tons of carbon per ton of clinker produced.

Across steel, cement, and glass industries, refractories are essential for maximizing equipment performance. By selecting the appropriate materials—whether acidic, basic, or neutral—companies do not just protect their machinery; they lower operational costs and drive sustainability

~Shivam