For decades, noise control has relied on traditional methods—thicker walls, dense foams, and fibrous liners. These solutions work for mid- and high-frequency noise but struggle against low-frequency sounds below 300 Hz, such as industrial hums or HVAC tones. Blocking these frequencies typically requires bulky materials over 150 mm thick, which is impractical for compact machines, electric vehicles, and modern infrastructure.

Acoustic metamaterials (AMs) solve this challenge by using engineered geometry instead of material bulk. They enable thin, lightweight, and tunable structures that control sound at frequencies far below what traditional materials can handle.

Why Metamaterials Matter Today?

India’s fast-growing industrial, mobility, and infrastructure sectors face increasingly complex noise environments. AMs enable low-frequency noise control at sub-wavelength scales, making them ideal for:

- Industrial machinery and compressors

- EV motors and powertrains

- HVAC systems and ventilation ducts

- Building acoustics and smart-city infrastructure

By replacing mass with precision geometry, they provide high performance with lower thickness, lower weight, and better airflow compatibility.

How Acoustic Metamaterials Work?

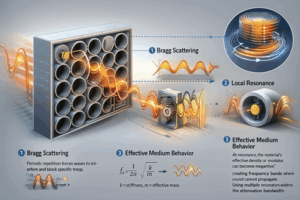

Unlike conventional absorbers that depend on density or porosity, AMs manipulate sound through structure. They are built from engineered unit cells—periodic or locally resonant elements smaller than the wavelength of sound.

Figure 1: Mechanism of acoustic metamaterials

Passive, Active, and Hybrid Designs

Passive AMs:

Rely purely on geometry. Used in compressor panels, sonic-crystal barriers, and ventilated duct liners. Durable and maintenance-free but typically narrowband.

Active AMs:

Integrate sensors and actuators to adapt in real time to changing noise environments. Useful for EVs and variable-speed machinery.

Hybrid AMs:

Combine passive geometry with active tuning, offering broadband, adjustable attenuation suitable for industrial and transport applications.

Real-World Example: 200 Hz Industrial Hum

A factory dealing with a persistent 200 Hz compressor tone implemented a 25 mm metamaterial panel containing polymer membranes with embedded aluminum masses. The membranes oscillated in opposite phase to the incoming noise, producing destructive interference.

Results:

20–24 dB noise reduction, Minimal airflow loss and 70% lighter than conventional acoustic panels.

Core applications across India

Industrial & Manufacturing: Effectively suppresses low-frequency tonal noise (50–250 Hz) generated by heavy machinery, such as textile equipment, compressors, pumps, and EV drive units.

Urban Infrastructure: Utilizes sonic-crystal barriers to mitigate traffic noise (50–500 Hz) while requiring only one-third of the thickness of traditional walls.

Buildings & HVAC: Employs ventilated metamaterial liners that reduce duct noise without compromising airflow. These offer superior moisture resistance and durability compared to traditional fibrous absorbers.

Moving Toward Smarter Noise Control

Acoustic metamaterials represent a shift from passive insulation to engineered sound control. By combining resonance tuning, advanced geometry, and adaptive mechanisms, they offer practical solutions for low-frequency noise—something traditional materials cannot provide without excessive bulk.

Emerging ideas like time-controlled “acoustic clock” architectures signal the next generation of dynamic noise-management systems. As research and industry collaborate, AMs will play a pivotal role in building quieter, more efficient, and sustainable environments across India.

~ Vatsal Parmar