If you’ve ever noticed moisture forming on chilled-water pipes, AHU lines, or

refrigeration lines, you’re witnessing a classic cold-insulation failure.

And here’s the truth:

Condensation is not a cooling issue — it’s an Insulation issue

Cold insulation isn’t just about keeping things cold; its real purpose is to stop heat and

moisture from entering the system.

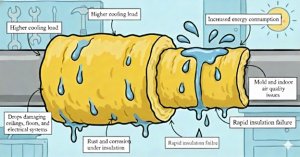

Why Condensation Is a Serious Problem!!

How to Prevent Condensation on Cold Pipes??

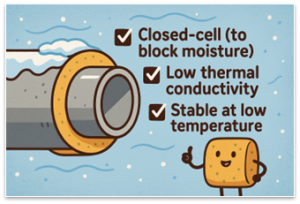

1. Select the right Insulation material

Best materials for cold applications include:

• Elastomeric foam (NBR, EPDM) – flexible, closed-cell

• PIR / PUF – rigid, low thermal conductivity

• Cross-linked PE foam

• Aerogel composites (premium)

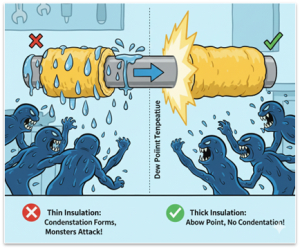

2. Use the correct Insulation thickness

Thickness MUST be enough to maintain:

outer surface > 𝑻dew point

Never guess thickness — always calculate.

3. Apply a proper vapor barrier

The vapor barrier is the heart of a cold insulation system.

It must be:

• Continuous

• Intact

• Properly sealed at all joints and seams

• High vapor resistance

4. Ensure zero gaps, cracks, or compression

Condensation forms at weak points first.

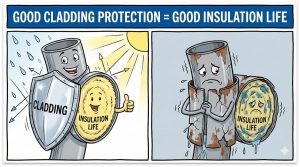

5. Protect Insulation externally

Cladding or jacketing protects cold insulation from:

• Mechanical damage

• Water exposure

• UV degradation (outdoor)

Cold insulation succeeds only when every layer works together. Correct material

selection, accurate thickness calculation, and a continuous vapor barrier form the

backbone of a reliable system.

Any weakness—whether a gap, crack, or damaged cladding—can turn into a condensation

hotspot that compromises performance.

~Khushi