Insulation is a crucial component in any industrial plant. It helps maintain equipment efficiency, conserves energy, and protects workers. At the same time, even the best insulation can hide a problem if moisture reaches the metal surfaces beneath. This is where Corrosion Under Insulation (CUI), becomes relevant. CUI occurs when water becomes trapped under insulation and slowly corrodes the metal. Because it is hidden, corrosion often goes unnoticed until inspections or maintenance reveal the damage.

How Trapped Moisture Turns into Costly Corrosion

From the outside, everything may look fine. Pipes are wrapped, cladding appears intact, and systems operate smoothly. However, small gaps, worn seals, or minor damage can allow moisture in. Once trapped, even a small amount of water creates an environment where corrosion can develop. This is why monitoring and preventive measures are so important. Studies have shown that CUI accounts for approximately 40 to 60 percent of piping maintenance expenditures in industries like oil and gas, chemicals, and power generation, highlighting the financial and operational impact of this silent threat.

Cracking the Code of CUI

Several factors contribute to CUI, including environmental conditions, the type of insulation, temperature fluctuations, and design flaws such as poor sealing or inadequate drainage. Certain insulation materials can absorb moisture or allow salts and electrolytes to interact with metal surfaces, leading to different types of corrosion, including galvanic corrosion, alkaline or acidic corrosion, and stress corrosion cracking. Understanding these factors is essential for effective prevention.

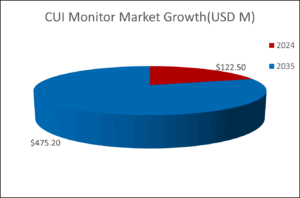

Advanced monitoring technologies are increasingly being adopted, with the global CUI monitoring market projected to grow from USD 122.5 million in 2024 to USD 475.2 million by 2035, reflecting the growing importance of predictive maintenance in extending equipment life and reducing downtime.

CUI is often called a silent threat because it develops quietly beneath the surface. It does not make noise or show immediate signs, yet over time it can compromise the integrity of metal surfaces. With awareness, proactive material selection, proper design, protective measures, and regular monitoring, CUI can be effectively managed. Preventing corrosion early is always more cost-effective than repairing damage later.

Insulation remains one of the most valuable elements in any industrial plant. It continues to protect equipment, conserve energy, and ensure operational safety. By understanding the risks of CUI and implementing preventive strategies, companies can ensure that insulation continues to perform its intended function, safeguarding piping systems and maintaining reliable operations for years to come.

~ Balram Patidar